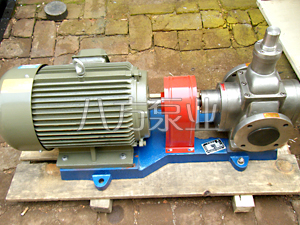

YCB不锈钢圆弧齿轮油泵

YCB不锈钢圆弧齿轮油泵主要输送机油、润滑油等有润滑性的介质,由于泵体是304不锈钢材质可以输送具有弱腐蚀性的介质,配用铜齿轮可输送低燃点液体,如汽油、苯等。YCB不锈钢齿轮油泵除配置普通电机外,还可根据用户需要配置同规格的防爆电机。

YCB不锈钢圆弧泵的材质有:201不锈钢、304不锈钢、316不锈钢等材质。YCB不锈钢圆弧齿轮油泵采用了国际上被认为输送泵最先进的一点连续接触齿轮,双圆弧加正弦曲线复合成齿形,可彻底淘汰渐开线齿轮输送泵。圆弧齿轮泵在两啮合齿廓间为一点连续接触,不会产生困油现象,彻底解决了渐开线齿轮泵因困油现象导致泵的振动,噪声,轴承负载增大等现象。因此YCB不锈钢圆弧齿轮泵结具有效率高,噪声低,并具有良好的节能效果。YCB不锈钢圆弧泵设有安全阀作为超载保护,安全阀全回流压力为泵额定排出压力的1.5倍。也可在允许排出压力范围内根据实际需要另行调整。但注意本安全阀不能作减压阀长期工作,需要时可在管路上另行安装。

YCB不锈钢圆弧齿轮油泵技术参数:

型号 | 流量 Q | 转速 n r/min | 排出压力 p Mpa | 必需汽 蚀余量 r m | 效率 η % | 电动机 | ||

m3/h | 频率 Hz | 功率KW | 型号 | |||||

YCB0.6-0.6 | 0.6 | 910 | 0.6 | 5.5 | 32 | 50 | 0.75 | Y90S-6 |

1.0 | 1390 | 50 | 0.75 | Y80L2-4 | ||||

0.7 | 1130 | 60 | 0.75 | Y90S-6 | ||||

1.2 | 1710 | 60 | 0.75 | Y80L2-4 | ||||

YCB0.6-1.6 | 0.6 | 910 | 1.6 | 7.0 | 70 | 50 | 1.1 | Y90L-6 |

1.0 | 1400 | 50 | 1.5 | Y90L-4 | ||||

0.7 | 1130 | 60 | 1.1 | Y90L-6 | ||||

1.2 | 1710 | 60 | 1.1 | Y90S-4 | ||||

YCB1.6-0.6 | 1.6 | 910 | 0.6 | 5.5 | 42 | 50 | 0.75 | Y90S-6 |

2.5 | 1400 | 50 | 1.1 | Y90S-4 | ||||

1.9 | 1130 | 60 | 1.1 | Y90L-6 | ||||

3.0 | 1710 | 60 | 1.5 | Y90L-4 | ||||

YCB1.6-1.6 | 1.6 | 940 | 1.6 | 7.0 | 71 | 50 | 2.2 | Y112M-6 |

2.5 | 1440 | 50 | 4 | Y112M-4 | ||||

1.9 | 1150 | 60 | 2.2 | Y112M-6 | ||||

3.0 | 1750 | 60 | 4 | Y112M-4 | ||||

YCB3.3-0.6 | 3.3 | 940 | 0.6 | 5.0 | 60 | 50 | 1.5 | Y100L-6 |

5.0 | 1420 | 50 | 2.2 | Y100L1-4 | ||||

4.0 | 1150 | 60 | 1.5 | Y100L-6 | ||||

6.0 | 1730 | 60 | 2.2 | Y100L1-4 | ||||

YCB3.3-1.6 | 3.3 | 960 | 1.6 | 7.0 | 72 | 50 | 5.5 | Y132M2-6 |

5.0 | 1440 | 50 | 7.5 | Y132M-4 | ||||

4.0 | 1170 | 60 | 4 | Y132M1-6 | ||||

6.0 | 1750 | 60 | 7.5 | Y132M-4 | ||||

YCB4-0.6 | 4.0 | 940 | 0.6 | 5.0 | 60 | 50 | 1.5 | Y100L-6 |

6.0 | 1420 | 50 | 2.2 | Y100L1-4 | ||||

4.8 | 1150 | 60 | 2.2 | Y112M-6 | ||||

7.2 | 1730 | 60 | 3 | Y100L2-4 | ||||

YCB4-1.6 | 4.0 | 960 | 1.6 | 7.0 | 72 | 50 | 5.5 | Y132M2-6 |

6.0 | 1440 | 50 | 7.5 | Y132M-4 | ||||

4.8 | 1170 | 60 | 5.5 | Y132M-6 | ||||

7.2 | 1750 | 60 | 7.5 | Y132M-4 | ||||

YCB8-0.6 | 8.0 | 960 | 0.6 | 5.0 | 61 | 50 | 3 | Y132S-6 |

12.0 | 1440 | 50 | 5.5 | Y132S-4 | ||||

9.6 | 1170 | 60 | 4 | Y132M1-6 | ||||

14.4 | 1750 | 60 | 5.5 | Y132S-4 | ||||

YCB8-1.6 | 8.0 | 970 | 1.6 | 7.0 | 75 | 50 | 11 | Y160L-6 |

12.0 | 1460 | 50 | 15 | Y160L-4 | ||||

9.6 | 1170 | 60 | 11 | Y160L-6 | ||||

14.4 | 1760 | 60 | 15 | Y160L-4 | ||||

YCB10-0.6 | 10.0 | 960 | 0.6 | 5.0 | 62 | 50 | 4 | Y132M1-6 |

15.0 | 1440 | 50 | 5.5 | Y132S-4 | ||||

12.0 | 1170 | 60 | 5.5 | Y132M2-6 | ||||

18.0 | 1750 | 60 | 7.5 | Y132M-4 | ||||

YCB10-1.6 | 10.0 | 970 | 1.6 | 7.0 | 76 | 50 | 11 | Y160L-6 |

15.0 | 1470 | 50 | 15 | Y160L-4 | ||||

12.0 | 1170 | 60 | 11 | Y160L-6 | ||||

18.0 | 1770 | 60 | 18.5 | Y160L-4 | ||||

YCB20-0.6 | 20.0 | 970 | 0.6 | 5.0 | 68 | 50 | 7.5 | Y160M-6 |

24.0 | 1170 | 60 | 7.5 | Y160M-6 | ||||

YCB25-0.6 | 25.0 | 970 | 0.6 | 5.5 | 69 | 50 | 11 | Y160L-6 |

30.0 | 1170 | 60 | 11 | Y160L-6 | ||||

YCB30-0.6 | 30.0 | 970 | 0.6 | 5.5 | 70 | 50 | 11 | Y160L-6 |

36.0 | 1170 | 60 | 11 | Y160L-6 | ||||

YCB40-0.6 | 40.0 | 970 | 0.6 | 5.5 | 72 | 50 | 15 | Y180L-6 |

48.0 | 1180 | 60 | 15 | Y180L-6 | ||||

YCB50-0.6 | 50.0 | 970 | 0.6 | 5.5 | 72 | 50 | 22 | Y200L2-6 |

60.0 | 1180 | 60 | 22 | Y200L2-6 | ||||