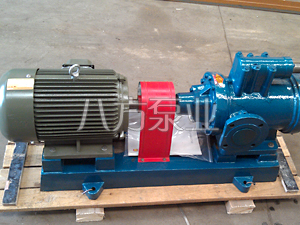

3G三螺杆泵

3G三螺杆泵是一种螺杆式容积泵,主要是利用螺杆啮合的原理,依靠旋转的螺杆在泵套内相互啮合,把被输送的介质封闭在啮合腔内,沿螺杆轴向连续匀速地推至排出口,为系统提供稳定的压力。3G三螺杆泵适用于输送各种无腐蚀性油类及类似油和润滑性液体。输送液体的粘度范围一般为3.0~760mm2/S(1.2~100°E),高粘度介质可通过加温降粘后输送。其温度一般不超过350℃。

3G三螺杆泵是螺杆式容积泵,由于主动螺杆与从动螺杆上螺旋槽相互啮合及它们与衬套三孔内表面的配合,得以在三螺杆泵的进出口之间形成数级动密封腔室,这些动密封腔室将不断把液体由泵进口轴向移动到泵出口,并使所输送液体逐渐升压,从而形成一个连续,平稳,轴向移 动的压力液体。

3G三螺杆泵特点:

1、介质为直线连续输送,无搅拌,无脉动;

2、振动小,噪音;

3、压力高、效率高;

4、结构简单、拆装方便;

5、体积小重量轻;

6、磨损轻微,寿命长。

型号 | 排出压力 P MPa | 流量 Q | 转速n r/min | 必需汽蚀余量 rm | 效率η % | 电动机 | ||

m3/h | L/min | 功率kw | 型号 | |||||

25×4-46 | 1.0 | 0.8 | 13 | 1450 | 4 | 62 | 0.75 | Y802-4 |

2.5 | 0.6 | 10 | 60.6 | 1.5 | Y90L-4 | |||

1.0 | 2.0 | 33 | 2900 | 4.5 | 59.4 | 1.5 | Y90S-2 | |

2.5 | 1.6 | 26 | 69 | 3 | Y100L-2 | |||

| 30×4-46 | 1.0 | 1.6 | 26 | 1450 | 4.5 | 63.5 | 1.1 | Y90S-4 |

2.5 | 1.2 | 20 | 61 | 2.2 | Y100L1-4 | |||

1.0 | 3.6 | 60 | 2900 | 5 | 60 | 2.2 | Y90L-2 | |

2.5 | 3.2 | 53 | 69 | 4 | Y112M-2 | |||

36×4-46 | 1.0 | 2.8 | 46 | 1450 | 4.5 | 66 | 2.2 | Y100L1-4 |

2.5 | 2.4 | 40 | 66.5 | 4 | Y112M-4 | |||

1.0 | 6.5 | 108 | 2900 | 5 | 60.5 | 4 | Y112M-2 | |

2.5 | 6 | 100 | 72 | 7.5 | Y132S2-2 | |||

42×4-46 | 1.0 | 4.8 | 80 | 1450 | 5 | 62 | 4 | Y112M-4 |

2.5 | 4.2 | 70 | 73 | 5.5 | Y132S1-4 | |||

1.0 | 10.5 | 175 | 2900 | 5.5 | 61 | 5.5 | Y132S1-2 | |

2.5 | 10 | 166 | 72 | 15 | Y160M2-2 | |||

45×4-46 | 1.0 | 6.3 | 106 | 1450 | 5 | 70 | 3 | Y100L2-4 |

2.5 | 5.9 | 99 | 74 | 7.5 | Y132M-4 | |||

1.0 | 13.5 | 225 | 2900 | 5.5 | 60 | 7.5 | Y132S2-2 | |

2.5 | 13 | 217 | 75 | 15 | Y160M2-2 | |||

| 60×4-46 | 1.0 | 15.5 | 255 | 1450 | 5 | 71.3 | 11 | Y160M-4 |

2.5 | 14.5 | 245 | 74 | 15 | Y160L-4 | |||

1.0 | 32 | 533 | 2900 | 5.5 | 63 | 18.5 | Y160L-2 | |

2.5 | 31.5 | 525 | 77 | 37 | Y200L2-2 | |||

70×2-46 | 0.6 | 24 | 400 | 1450 | 5 | 71 | 7.5 | Y132M-4 |

1.0 | 23.5 | 390 | 75 | 11 | Y160M-4 | |||

1.6 | 22.5 | 370 | 76 | 15 | Y160L-4 | |||

| 70×4-46 | 1.0 | 24.5 | 408 | 1450 | 5 | 72.5 | 18.5 | Y180M-4 |

2.5 | 23.5 | 392 | 79 | 30 | Y200L-4 | |||

| 80×2-46 | 0.6 | 36.5 | 608 | 1450 | 5 | 72 | 11 | Y160M-4 |

1.0 | 35 | 594 | 75.5 | 18.5 | Y180M-4 | |||

1.6 | 34.5 | 575 | 76.5 | 22 | Y180L-4 | |||

| 80×4-46 | 1.0 | 37 | 617 | 1450 | 5.5 | 72 | 30 | Y200L-4 |

2.5 | 35 | 590 | 78.1 | 45 | Y225M-4 | |||

100×2-46 | 0.6 | 72.5 | 1208 | 1450 | 5 | 73 | 22 | Y180L-4 |

1.0 | 71 | 1183 | 77 | 37 | Y225S-4 | |||

1.6 | 60.5 | 1158 | 79 | 45 | Y225M-4 | |||

100×4-46 | 1.0 | 72.5 | 1208 | 1450 | 5.5 | 73 | 55 | Y250M-4 |

2.5 | 70 | 1165 | 78.5 | 75 | Y280S-4 | |||

| S100×3-27 | 0.6 | 72 | 1196 | 1450 | 6 | 62 | 22 | Y180L-4 |

1.6 | 70 | 1160 | 72 | 55 | Y250M-4 | |||

2.5 | 69 | 1145 | 74 | 75 | Y280S-4 | |||

S120×3-27 | 0.8 | 123 | 2055 | 1450 | 6 | 74.5 | 55 | Y250M-4 |

1.5 | 120 | 2010 | 76 | 90 | Y280M-4 | |||

2.5 | 115 | 1920 | 78.5 | 132 | Y315M-4 | |||